Top > Checking fixture technology

Checking fixture technology

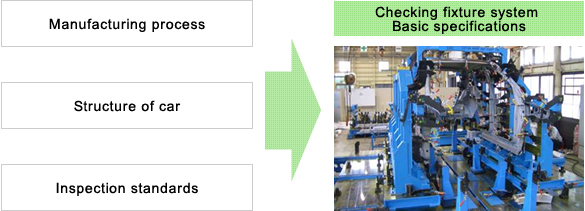

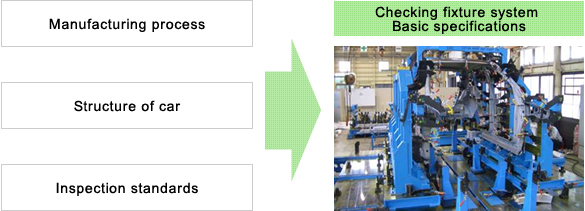

We can plan and propose checking fixture system, can create checking fixture specification, can design, manufacture and inspect checking fixture consistently by the technology of checking-fixture.com in Japan and worldwide.

| Technology1 |

|

Planning and proposal of checking fixture system

We can plan the checking fixture system to be able to verify a lot of car manufacture ring process in Japan and worldwide.

|

(Know-how) |

1.We understand car manufacture process in detail.

2.We can plan the checking fixture system to verify car manufacture.

3.We are familiar with required accuracy for car manufacture.

4.We have know-how of fit and finish operation between parts. |

(Experience) |

1.We have know-how for car manufacturing facility,

and are familiar with important point to assure the quality.

2.We have a lot of actual results for checking fixture manufacture of

car manufacturer and parts manufacturer in Japan and worldwide. |

| |

|

| Technology2 |

|

Specification creation

We can create checking fixture specification wit understanding of locating function between car and parts and, required accuracy. |

| ●Specification creation know-how |

| |

1.We create checking fixture specification with these characteristic information.

considering located accuracy condition between car and parts,

2.We can create checking fixture specification considering located parts

in each car manufacturing process.

3.We can create checking fixture specification considering required accuracy

of car and parts.

4.We can create checking fixture specification considering

the way to use and measurement facility. |

●Long stay of our engineers |

|

| Technology3 |

|

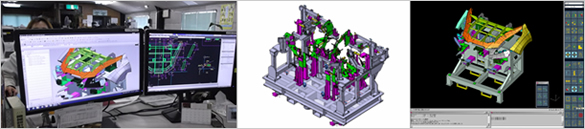

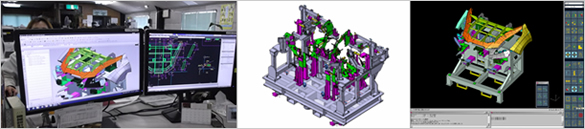

Design technology

~Design capability by veteran design engineer know-how and technical data base~ |

| ●Design technology/organization |

| |

1.High-end CAD CATIA V5 / NX / iDEAS |

| |

|

| |

2.A lot of veteran engineer :

Technical informations are shared by technical data base.

3.35 Design engineers |

| |

|

| |

4.The best frame design to realize the best weight,

strength and accuracy(+0.05/-0.05) by FEM analysis |

| |

|

| |

5.We can design and manufacture accurate large mock-up (checking fixture)

to prevent to be deformed by own weight.

・We ensure the strength keeping required shape.

・We ensure big mock-up (checking fixture) accuracy without frame

to prevent to be deformed by own weight. |

| |

|

| |

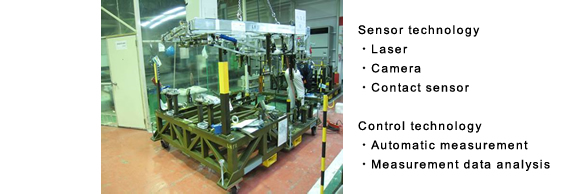

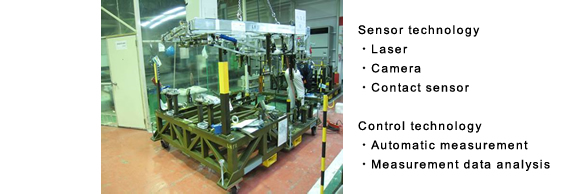

6.We have automatic measurement technology |

| |

|

| ●Creating CAM data |

| |

3D CAM CAM NX / DIPRO-α / WORK-NC |

| Technology4 |

|

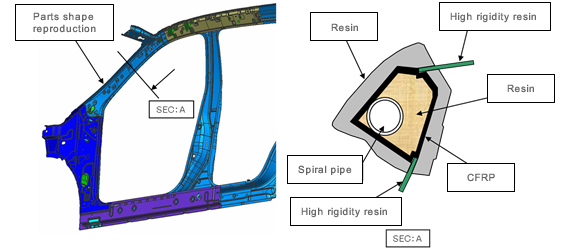

Machining technology

~Resin material technology and accurate 3D surface machining technology~ |

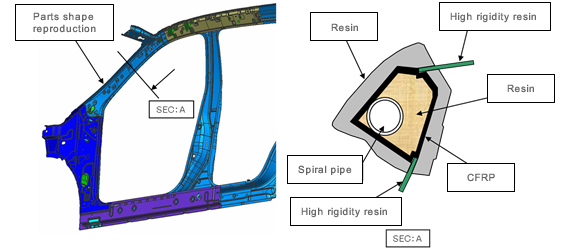

| ●material technology |

| |

1.We can select the best material based on the purpose such as resin,

CFRP, aluminum.

2.We can adjust the resin material as the suitable condition with resin suppliers.

3.We have additives knowledge in resin material.

(Required strength, coefficient of thermal expansion, machining workability)

We have mixing technology of resin material and addition agent keeping good relationship with resin supplier to realize required work specification. We decide the best mixing ratio of addition agent to achieve required strength (stickiness, surface hardness, anti-shock) and required coefficient of thermal expansion .

|

| |

|

| |

詳しくは →  |

| |

| ●material procurement |

| |

1.We can select and procure the best material fit for specification

from the local procurement materials. |

| ●machining technology |

| |

3D surface / accurate machining technology.

・Resin

・CFRP

・Aluminum

・Steel

・Casting |

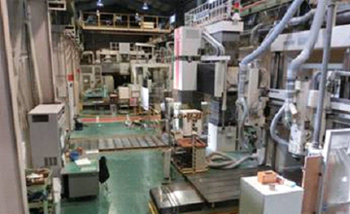

| ●machining center |

| |

Large size 5 axis machining center, 5 surface machining center

We have a lot of large size 5 axis machining center, 5 surface machining center in checking-fixtures.com. We have various equipments for mainly resin machining, with reference to factory and equipment list in detail. |

| |

Large NC machining center.

Shin nippon koki RB-150F 5 axis machining center

|

|

Large NC machining center.

Okuma MCR-A 5 axis machining center

|

Large NC machining center.

Okuma MCR-B11-HP 5 axis machining center

|

|

Large NC machining center.

Okuma MCV-20A 5-face machining center |

|

| |

≫Factory ≫Equipment list

|

| |

3Dプリンター |

| |

Fused deposition modeling : 3D production systems

|

|

Selective Laser Sintering:Stratasys

|

|

| Technology5 |

|

Manufacture/Assembly

~We can manufacture 3-4 m checking fixtures in size within 0.05mm accuracy by assembly technology and equipments~ |

●facility |

1.Thermostatic factory |

| |

Resin and plastic are delicate. The shape is changed by change in temperature or in humidity. It is very important to control machining circumstance such as temperature and humidity to achieve machining quality on resin and plastic. We investigate to control machining circumstance such as temperature and humidity as same as we investigate machining tool in checking-fixture.com. We manufacture all products in 22 degrees celsius in thermostatic factory to keep stable condition for resin and plastic. |

|

|

|

| |

2.We assure the quality by accurate measurement machine from assembly stage. |

| |

| |

・TOKYO BOEKI TECHNO-SYSTEM LTD.

thomas 2015J (2台)

・定盤 4,000mm×6,000mm×400H |

|

|

| ●assembly technology |

| |

1.We can achieve the required accuracy in large checking fixture.

(0.05mm accuracy in 3-4m size checking fixture for car) |

| |

|

| |

2.We have a lot of skillful staffs who are familiar with important point for accuracy. |

| |

|

●Modification |

1.We can modify(change) the checking-fixtures designed and manufactured

by the other company.

2.We can repair and retrofit long-term use checking-fixtures. |

| Technology6 |

|

Inspection organization

~Reliable inspection system by thermostatic factory and accurate measurement machine, laser measurement machine~ |

| ●Thermostatic factory / accurate measurement machine / laser measurement machine |

| |

We have large 5-axis machining / machining center with 5-face machining equipment, and have another equipment for resin machining in in checking fixture.com |

| |

・TOKYO BOEKI TECHNO-SYSTEM LTD.

thomas 2015J (2台)

・定盤 4,000mm×6,000mm×400H |

|

・TOKYO BOEKI TECHNO-SYSTEM LTD.

thomas 2015J (2台)

・定盤 3,600mm×6,000mm×250H |

| |

・TOKYO BOEKI TECHNO-SYSTEM LTD.

layout machine 2015F+MEGAⅡ(2台)

・定盤 3,500mm×6,000mm×250H |

|

・TOKYO BOEKI TECHNO-SYSTEM LTD.

thomas 2015J (3台)

・定盤 3,000mm×5,000mm×250H (2面) |

| |

・TOKYO BOEKI TECHNO-SYSTEM LTD.

thomas 1015system (1台)

・定盤 3,000mm×4,000mm×300H |

|

|

|

|

・多間接型三次元測定機ベクトロン

VMC6666Mpls (2台)

・非接触計測システム (レーザースキャナー) |

|

|

●人材 |

1.Inspectors can operate 3D high-end CAD

2.Our staffs can supervise checking fixture installation,

maintenance and modification. |